What is GFRP Rebar? Uses, Advantages, And Applications.

What is GFRP Rebar?

GFRP rebar, or Glass Fiber Reinforced Polymer rebar, is a non-metallic construction material used to reinforce concrete structures. It is made from Glass Fiber and Polymer Resin matrix. This results in a rebar that's lightweight, strong, and highly resistant to corrosion, making it a promising alternative to traditional steel rebar.

Composition of GFRP Rebar

GFRP Rebar or Glass Fiber Reinforced Polymer Rebar consists of Glass Fiber and Polymer Resin. Glass Fiber provides more strength and Polymer resin holds everything together and protects it.

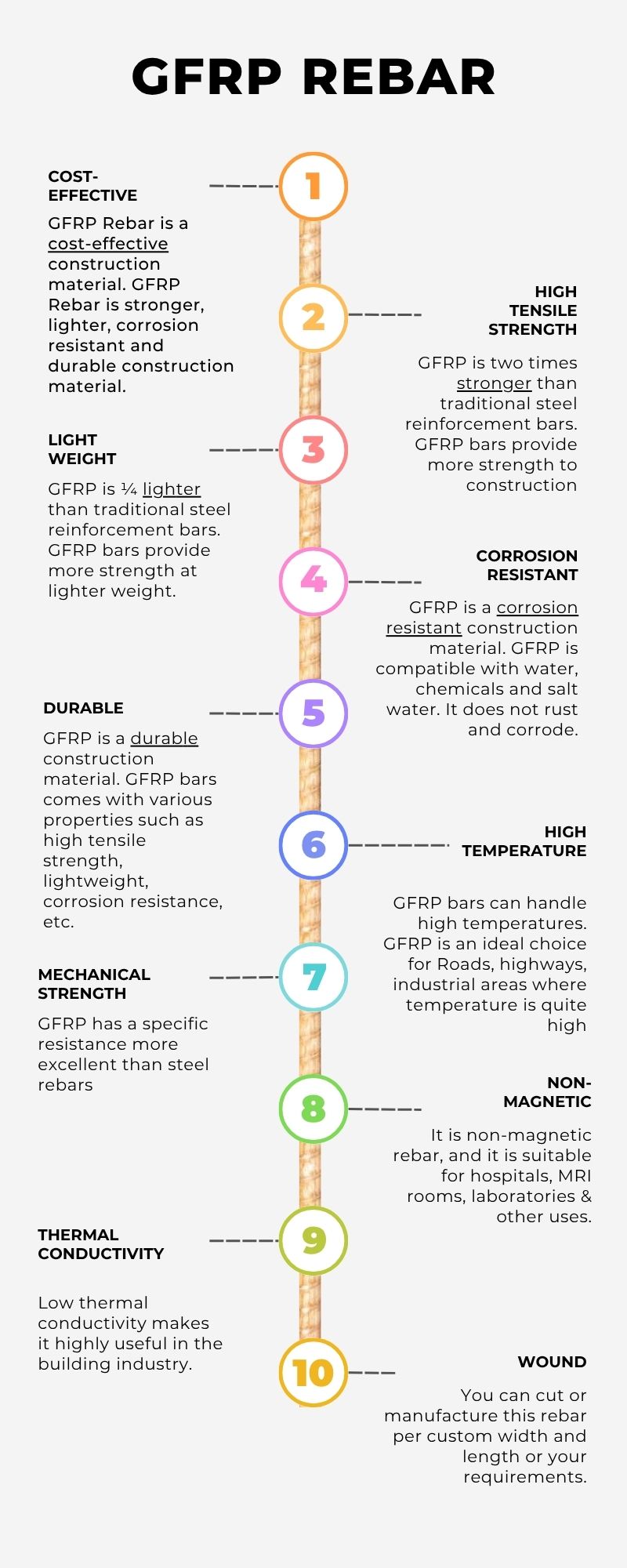

Key Properties of GFRP Rebar

- Cost-effective:- GFRP Rebar is a cost-effective construction material. GFRP Rebar is stronger, lighter, corrosion resistant and durable construction material. By using GFRP Rebar construction does not require regular maintenance and replacement.

- High Tensile Strength:- GFRP is two times stronger than traditional steel reinforcement bars. GFRP bars provide more strength to construction.

- Light Weight:- GFRP is ¼ lighter than traditional steel reinforcement bars. GFRP bars provide more strength at lighter weight. It is an ideal construction material where construction weight is a major concern. For example Bridges, highrise buildings, etc.

- Corrosion Resistant: GFRP is a corrosion resistant construction material. GFRP is compatible with water, chemicals and salt water. It does not rust and corrode. It is an ideal choice for marine structure, dam, Bridges on water, deck, etc.

- Durable: GFRP is a durable construction material. GFRP bars comes with various properties such as high tensile strength, lightweight, corrosion resistance, etc. These properties make GFRP durable construction material.

- High Temperature:- GFRP bars can handle high temperatures. GFRP is an ideal choice for Roads, highways, industrial areas where temperature is quite high.

- Mechanical strength:- GFRP has a specific resistance more excellent than steel rebars.

- Non-Magnetic:- It is non-magnetic rebar, and it is suitable for hospitals, MRI rooms, laboratories & other uses.

- Thermal conductivity:- Low thermal conductivity makes it highly useful in the building industry.

- Wound:- You can cut or manufacture this rebar per custom width and length or your requirements.

Applications of GFRP Rebar

- GFRP Rebar For Marine structures : GFRP is a corrosion resistant construction material. It does not rust and corrode. GFRP bars are compatible with water. GFRP is an ideal choice for marine and coastal structures.

- GFRP Rebar Bridges construction: Bridges are important construction. It enables two destinations for people to travel. Bridges also help in travel, economic development, and transfer goods.

- GFRP Rebar for Tunnels : GFRP is corrosion resistant, durable, stronger and lighter construction material. GFRP bars make the tunnel stronger at lighter weight.

- GFRP Rebar For Roads construction: Road and highways go through heavy vehicles and are used for transportation, transfer goods. Roads and highways also go through high temperatures so it requires a construction material that can handle high temperatures. GFRP is stronger, corrosion resistant, and can handle high temperatures.

- GFRP Rebar For Base slab and Industrial Floors: GFRP bars are highly effective for base slab and industrial floors. Its corrosion-resistant properties ensure long-term durability, especially in areas where traditional steel reinforcement would deteriorate. It’s lightweight properties simplify transportation and installation.

- GFRP Rebar For swimming Pool construction: GFRP is a corrosion resistant construction material. It is compatible with water. The swimming pool is filled with water, so the pool requires a material which is compatible with water. By using GFRP bars in the swimming pool, it does not require regular maintenance and replacement.

- GFRP Rebar For Septic tank:- The septic tank is an underground concrete chamber through which domestic water waste flows for essential sewage treatment. GFRP is an exceptional choice for septic tank construction. GFRP is a corrosion resistant material it is compatible with water, salt water and chemicals. Unlike steel rebar it does not rust and degrade the septic tank construction. Its lightweight nature also makes handling and installation easier, especially in precast or on-site applications. Overall, GFRP enhances durability while reducing maintenance and lifecycle costs in septic tank construction.

GFRP Rebar Vs. Steel rebar

- Stronger: GFRP is two times stronger than traditional steel reinforcement bars. GFRP bars makes the construction stronger. It is an ideal choice for Roads, highways, bridges, etc. where High tensile strength is a major concern.

- Lighter: GFRP bars are ¼ lighter than traditional steel rebar. GFRP makes the construction more stronger at lighter weight. It is an ideal choice where weight is a major concern, For example bridge construction, high rise buildings, etc.

- Cost-effective: GFRP bar is a durable construction material. By using GFRP bars construction does not require regular maintenance and replacement. GFRP is also lightweight construction material so installation and transportation cost is also low. It saves the money.

- High temperature: GFRP bars can handle high temperatures. It is an ideal choice where temperature is major concern.

- Corrosion resistant: GFRP does not rust and corrode while steel rebar is not compatible with water. GFRP bars are compatible with water. Glass Fiber Reinforced Polymer is an ideal choice for marine structure, deck, dam on water, etc. Steel rebar is not corrosion resistant material. By using steel rebar construction weaken and some time construction requires replacement.

For more details you can check GFRP Rebar vs steel rebar.

The Manufacturing Process of GFRP Rebar

The General Process for manufacturing of GFRP.

- Batching:- It is the initial stage of the process, where the material must be weighed in exact quantity and mixed very well. Silica sand is mixed with glass. It is an essential thing used for making glass.

- Melting:- From batching section, the materials are sent for the melting process. First, they melt the material at a high temperature, and their melting occurs, and uniformity is increased, ensuring no bubbles. At high temperatures, sand and other materials dissolve into the glass.

- Fiberization:- Fiberisation is the process that includes a combination of extrusion and attenuation. In extrusion, the molten glass passes out of the erosion-resistant platinum alloy with very fine orifices, and plates are heated electronically. Their temperature is controlled to maintain a constant glass viscosity. Attenuation is the process of mechanically drawing the extruded streams of molten glass into fibrous elements called filaments.

- The coating is the final stage where the chemical coating is applied. Here lubricants, binders, and coupling things are also added. The lubricant helps to protect the filaments from rubbing and breaking. The chemical coating increases a little bit of weight.

- Drying and packaging:- finally, the material is collected in the bundle, and then as per requirement, packaging will occur.

MRG Composite Rebar

MRG Composites Rebar is the leading GFRP rebar manufacturer in India, offering high-quality and durable solutions for construction projects. As The Pioneers of GFRP rebars in India, MRG Composites sets the benchmark for innovation and reliability. With the best GFRP rebar prices in India, we ensure quality and reliability. Contact us for expert consultation and superior reinforcement solutions. GFRP Rebar is an ideal choice for all construction.

With over 17 years of industry expertise, MRG Composites stands as one of India's largest manufacturers and global suppliers of GFRP Rebar. Having successfully completed 3000+ projects and delivered more than 5000 metric tons of material worldwide, we are committed to quality, reliability, and innovation. Our 100% customer satisfaction rate reflects our dedication to excellence and trust, reinforcing our position as a leading name in the composites industry.

Conclusion

For construction, The construction should be solid and requires good material that fulfills the GFRP bars completely. This rebar went through so many processes and was tested at various levels, and then after, it will be used in construction.

GFRP Rebar FAQs

GFRP rebar, or Glass Fiber Reinforced Polymer rebar, is a non-metallic construction material used to reinforce concrete structures. GFRP Rebar is stronger, lighter, cost-effective, and corrosion resistant construction material.

Due to higher fatigue properties, GFRP have a higher resistance to cyclical loads of high intensity, which makes GFRP workable during earthquakes subject to a detailed design report on the same.

Any binding can be used while using GFRP. Traditional binding wires can be surely used as well as plastic clips or knitting wire with the help of plastic fix clips.

Yes, you can use MRG GFRP bars together with metal rebars in some cases where it is necessary.

All Categories

Recent Posts

GFRP Rebar vs. Steel Rebar: Strength, Durability & Benefits

GFRP Rebar for Foundation Construction

MON-SAT 8:00-9:00

+91 69 863 6420