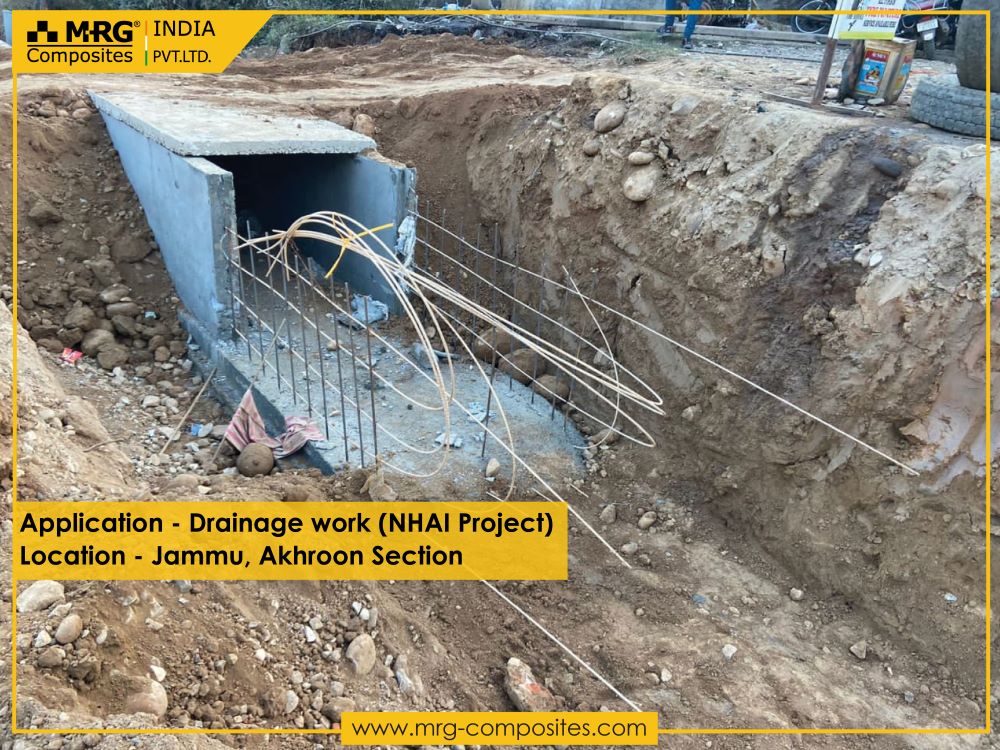

Jammu Drainage Work

MRG Composites Rebar was tasked with reinforcing drain infrastructure in Jammu, a region known for its diverse weather conditions and frequent rainfall. The project aimed to enhance the durability and longevity of the drainage system, which is crucial for managing stormwater and preventing flooding. We provided Glass Fiber Reinforced Polymer (GFRP) rebar, offering a modern solution for the construction and reinforcement of the drain system.

Challenges Faced

- Weather Variability: Jammu’s climate features heavy rainfall and varying temperatures, which can lead to rapid wear and corrosion of traditional steel reinforcement in drains.

- High Corrosion Risks: Exposure to water and sediment can accelerate the deterioration of steel rebar, leading to costly maintenance and repair issues.

- Structural Integrity Needs: The drain system required strong, durable reinforcement to handle high volumes of stormwater and resist potential structural damage over time.

Solutions Implemented

- Incorporation of GFRP Rebar: We selected GFRP rebar for its superior resistance to corrosion and weather conditions. GFRP rebar does not rust or weaken when exposed to water, making it ideal for drain systems in Jammu’s challenging environment.

- Enhanced Durability: GFRP rebar’s high tensile strength and resistance to environmental stress ensured that the drains would maintain their structural integrity even under heavy stormwater flow and temperature fluctuations.

- Reduced Maintenance Requirements: By using GFRP rebar, we significantly decreased the need for future maintenance. The material’s resistance to corrosion and wear reduces long-term repair costs and extends the lifespan of the drainage system.

Project Outcome

We completed the drain work in Jammu efficiently, adhering to project timelines and budget constraints. The reinforced drains have exhibited excellent performance, effectively managing stormwater without signs of deterioration. The use of GFRP rebar has provided a reliable, low-maintenance solution that enhances the overall resilience of the drainage infrastructure.

Conclusion

MRG Composites Rebar’s implementation of GFRP rebar in Jammu’s drain work highlights our commitment to delivering innovative and durable solutions for infrastructure projects. Our approach ensured the drains can withstand the region’s demanding weather conditions, providing a long-lasting and cost-effective solution for managing stormwater and preventing flooding.