Trusted GFRP Rebar Manufacturers in India

Best GFRP Rebar Price Guaranteed

- Stronger

- Lighter

- Cost-Effective

Continuous Betterment

Cost

Efficiency

Reliability Consistently

MRG Composites

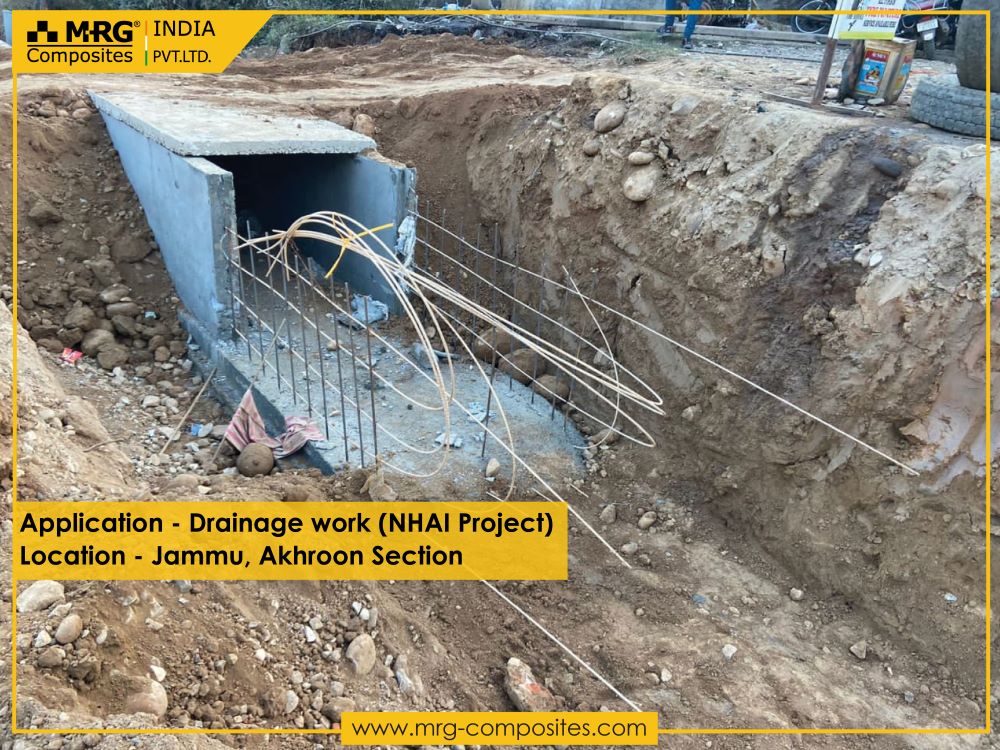

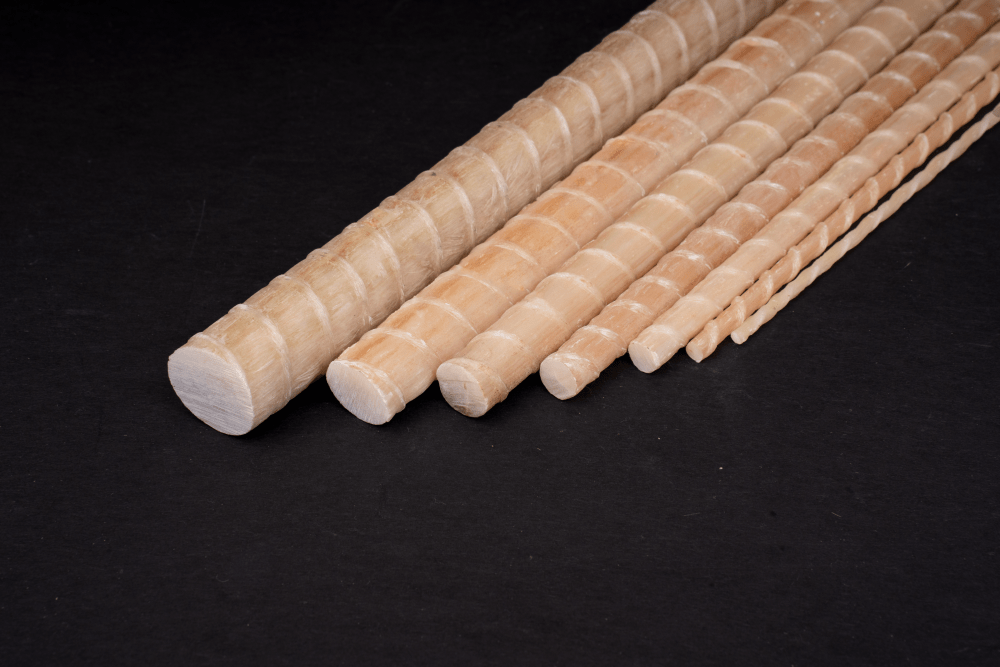

The “Machine Retail Group” (MRG) was established in 2007. The company is actively engaged in the introduction of modern equipment in the industrial complex of Russia and India. MRG Composites specializes in the production of GFRP (Glass Fibre Reinforced Polymers) Rebars since 2007. Our Rebars carry high tensile strength and are 2 times stronger and 4 times lighter than iron Rebars. It is currently East Africa, UAE, & India’s most cost- effective material for structural and road construction projects. Two brothers, Neel Vaya and Bhavik Vaya along with Amit Gangurde set their entrepreneurial journey and started MRG- Composites India operations in early 2019. There has been no looking back since then. Today, within a short span despite the pandemic, MRG-Composites India has achieved the remarkable feat of becoming India’s Largest Manufacturer & Supplier of GFRP Rebars as well as becoming India’s No. 1 selling GFRP rebars brand

Glass Fiber Reinforced Polymer - GFRP Rebar

GFRP (Glass Fiber Reinforced Polymers) Rebars are the best composite rebar for construction material and building material. The use of GFRP composites rebars increased very well in the construction business. Our Rebars are two times stronger and 1/4 lighter than steel. Our rebars include high-quality corrosion-resistant epoxy resin that increases the lifespan of a concrete structure. GFRP Rebar is made of Glass Fiber and Polymer Rebar. Fiber Glass protects polymer resin.

MRG Composite Rebar has the best GFRP (Glass Fiber Reinforced Polymers) rebar price in India. We are the leading GFRP rebar manufacturer in India.

Trusted By

The Indian Government

Shri Nitin Gadkariji

(Minister of Road Transport & Highways)

MRG GFRP Rebar Advantages

Corrosion Resistant

Stronger

Lighter

Cost Effective

Zero Maintenance

Longer Life Span

Corrosion Resistant

Stronger

Lighter

Cost Effective

Zero Maintenance

Longer Life Span

Shri Nitin Gadkariji

Minister of Road Transport and Highways of India

MRG Composites

The Pioneers Of GFRP Rebars In India.

4.5 out of 5 customers give us 5 stars?

Commitment to High-Quality Standards

Core Values

Integrity

Quality

Ethics

Sleeve Up Approach

Contact Us

Address

Office No 601, Twin Star South Block, Near Nanamava Circle, 150 Feet Ring Road Rajkot- 360004

Client Reviews

Rajesh

Ahmed Al Mansoori

Vikram

Yes, you can use MRG GFRP Rebars together with metal rebars in some cases where it is necessary.

Composite reinforcement is fire resistant up to 600 degrees Celsius. Once the temperature exceeds 600 degrees Celsius, the compound that binds the composite reinforcement fibers softens. Composite reinforcement does not burn directly, and studies show that structures are sustainable during a fire.

No, as the mechanical properties of GFRP Rebars are elastic, thus it does not allow you to bend the material on site. However, you can get your desired bend/curved elements prefabricated as per your requirement.