Glass Fiber Reinforced Polymer (GFRP Rebar) is an alternative to steel bars. Glass fibre Reinforced polymer is a composite material made of glass fibre embedded in a polymer matrix.

It is a lightweight, more robust, cost-effective material. In addition, GFRP bar does not corrode to rust like steel reinforced bars. GFRP bar is an excellent choice for construction. This bar is designed to replace the traditional steel bars and provides more advantages.

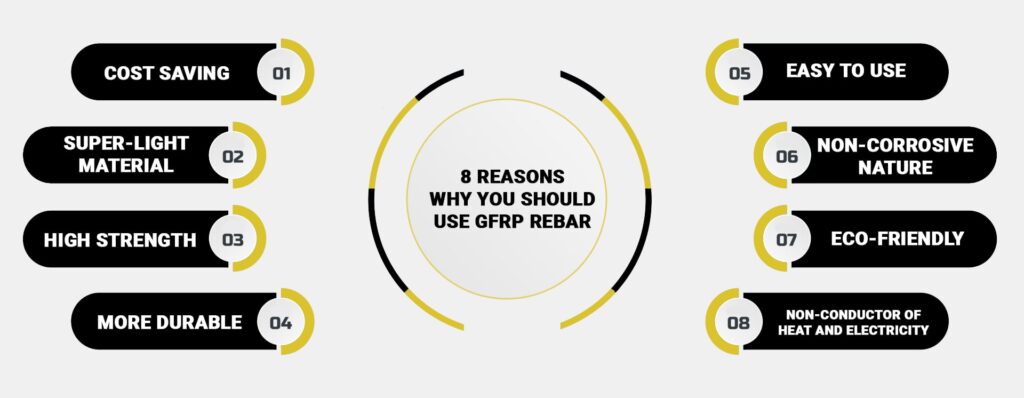

Cost is an essential factor for the construction business. GFRP bars are durable material and provides more lifespan for concrete structures. It saves the maintenance cost of construction. GFRP bar is a lightweight material that makes it easy to transport from one location to another. You can bend these bars, making it easy to load rebars on the vehicle. GFRP bars are flexible and easy-to-install material. It decreases labor costs and speeds up construction times.

Glass Fiber Reinforced Polymer has gained popularity in construction. GFRP bar is two times stronger than steel bars material. GFRP bars’ composition makes it more strength table material. The highly tensile strength of GFRP bar comes from the combination of the tensile strength of the glass fibers and the strength of the polymer matrix. Glass fibre provides the necessary strength, and the polymer matrix protects fibers and transfers the load to them. Glass fibers are aligned to and coated with a polymer matrix to ensure that they are fully embedded and protected.

GFRP Rebar is a lightweight material due to the low density of both the glass fibers and the polymer matrix. Glass fibre polymer rebar is a lighter material than steel bars and provides more strength to the construction. It is easy to transport rebars from the manufacturing unit to the site.

GFRP Rebar is more corrosion resistant material than steel bars. It is made up of glass and protects from rust and other forms of corrosion that can weaken steel bars over time. GFRP bar is a stronger material than steel bars. It increases the life span of a structure or construction.

GFRP Rebar is a lightweight material that is very easy to install or use. You can cut bars as per your requirements. You can bend these rebars and transport them to your construction site.

GFRP Rebar is corrosion resistant material, unlike steel bars. GFRP bar comprises glass fibers and resin that protect it from corrosion elements such as chemicals, moisture, salt, etc. GFRP bars are beneficial in harsh conditions such as coastal lines and marine lines. GFRP Rebar increases the life span of construction due to its corrosion-resistant advantage.

GFRP Rebar is made of recyclable material, whereas steel bars are made of finite resources. GFRP Rebar manufacturing requires a low carbon footprint compared to steel bars.

GFRP Rebar does not conduct heat, reducing the risk of fire spreading through the structure. The lack of metallic components in its composition makes it a poor conductor of heat and electricity. The polymer matrix and glass fibre are poor conductors of heat.

MRG Composite Rebar is a leading GFRP Rebar manufacturers in india and supplies worldwide. Our bars are stronger, lighter, and cost-effective than steel reinforcement bars. We are best known for our GFRP rebar. Our GFRP bars are the perfect choice for bridge construction.

MRG Composite Rebar can provide high-quality industrial flooring. One of our specialities is in flooring for industrial and commercial clients. Our floors can help you keep your business look best. We offer a variety of flooring options to choose from.

[wpforms id=”6454″]